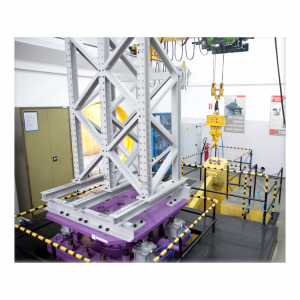

The purpose of MIL-S-901D test is to verify the ability of shipboard installations to withstand shock loadings which may be incurred during wartime service due to the effects of nuclear or conventional weapons.

Underwater Explosion Shock Testing (MIL-S-901D)

Tekno - ETA > Underwater Explosion Shock Testing (MIL-S-901D)

Shipboard shock testing involves two types of device:

Grade A

-

- Grade A items are items which are essential to the safety continued combat capability of the ship.

Grade B

-

- Grade B items are items whose operation is not essential to the safety and comat capability of the ship but which could become a hazard to personnel, to grade A items, or to the ship as a whole as a result of exposure to shock.

Along with the categories of test and grades of equipment, MIL-S-901D classifies equipment in based on mounting requirements of the equipment. These requirements define the mounting of the shipboard equipment being able to meet the shock, noise or vibration requirements with or without the use isolation equipment. Testing requirements for devices in each class are determined by the way they are installed in the ship:

Class I

-

- Class I equipment is defined as that which is required to meet these shock requirements without the use of resilient mountings installed between the equipment and the ship structure or foundation.

Class II

-

- Class II equipment is defined as that which is required to meet these shock requirements with the use of resilient mountings installed between the equipment and the ship structure or shipboard foundation.

Class III

-

- Unless otherwise specified, class III equipment is defined as that which has shipboard application both with and without the use of resilient mountings and is therefore required to meet both class I and class II requirements.

In addition to the types of shock testing classifications and shipboard equipment mounting requirements, MIL-S-901D also classifies shock test types with the following Test Types:

Type A

-

- Type A test is a test of a principal unit. This is the preferred test. Principal units are items whitch are directly supported by the ship structure or by a foundation which is directly attached to the ship structure, and items mounted in piping systems, ducting systems, and simiilar systems which are supported by the ship structure. The shock response of a principal unit is primarily a function of the rigidity and mass of the item and the shipboard mounting structure, the shipboard mounting location, and the configuration of the item. Such items typically include diesel-genetaror sets, air conditioning plants, switchboards, radio transmitters, steam generators, missile launchers, and valves ( if installed in piping which is supported by the ship structure).

Type B

-

- Type B test is a test of a subsidiary component. Subsidiary components are items which are the major parts of a principal unit. The shock reponse of the subsidiary component is significantly affected by that of the subsidiary component. Examples are the diesel engine of a diesel-generator set, the electric motor of an air conditioning unit, or the power supply section of a radio transmitter.

Type C

-

- Type C test is a test of a subassembly. Subassemblies are items which are a part of a principal unit or a subsidiary component. The shock response of the subassembly is significantly affected by that of the associated principal unit or subsidiary component, but the shock response of the principal unit or subsidiary component is not significantly affected by the subassembly. Examples are thermometers, gagues, meters, relays, and resistors. This distinction between subassembly and assembly or part as used herein may be different than that used in various equipment specifications or other acquisition documents.