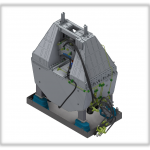

Static Characterization Testing (25 kN)

- In vertical axis (Z)

- Up to ±25 kN rated force capacity

- Up to ±25 mm deflection capacity

- Capability to define consecutive static deflection tests with different or same parameters

- Capability to define different or same test speeds for pre-test cycles and measurement test cycle

- Displacement and force controlled test speeds (mm/s, N/s)

- Defining displacement or force as type of test end levels

- Defining frame stiffnes to correct measured stiffness and calculate pure stiffness of part.

- Defining an external LVDT to measure pure stiffness of part directly.

- Calculating stiffnes by chord or tangential method from one or two defined points of loading or releasing arms of hysteresis curve or from one or two defined points of averaged curve of hysteresis by force or lenght averaging methods.

- Calculating stiffness for all data points

- Using a pre-load axis in horizontal dynamic test by force or deflection based control

- In horizontal axis (X)

- Up to ±5 kN rated force capacity

- Up to ±25 mm deflection capacity

- Capability to define consecutive static deflection tests with different or same parameters

- Capability to define different or same test speeds for pre-test cycles and measurement test cycle

- Displacement and force controlled test speeds (mm/s, N/s)

- Defining displacement or force as type of test end levels

- Defining frame stiffnes to correct measured stiffness and calculate pure stiffness of part.

- Defining an external LVDT to measure pure stiffness of part directly.

- Calculating stiffnes by chord or tangential method from one or two defined points of loading or releasing arms of hysteresis curve or from one or two defined points of averaged curve of hysteresis by force or lenght averaging methods.

- Calculating stiffness for all data points

- Using a pre-load axis in vertical dynamic test by force or deflection based control

- In horizontal axis (Y)

- Manually adjustment in Y direction

- Capability of adjusting alignment of test specimen to upper mounting interface of test system by powerscrew handle

- Up to ±2 kN rated force capacity with a load cell plate assembled by piezo-electric force trancducers for measuring and monitoring not controlling